Recommendations for sewing leather hides

Sewing leather is not the same as sewing faux leather. There are challenges that come with either type of material. Faux leather has a wide range of attributes, and in some cases the thicker and stiffer imitation leather fabrics are similar to a leather hide, whereas in other cases your setup may be geared for lighter-weight fabrics with high degrees of stretch for a 4-way stretch faux leather material. Regardless, you’ll need a different sewing setup and mindset for working with real leather.

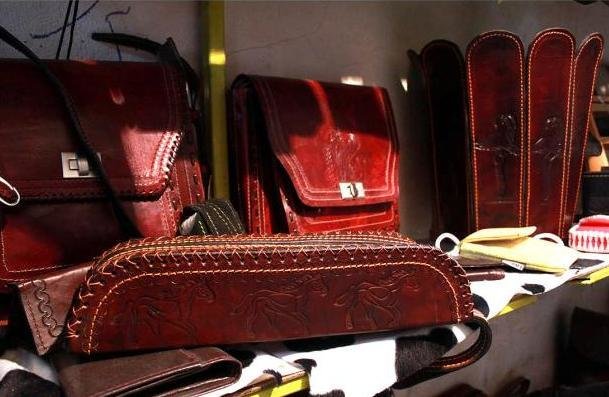

Leather hides tend to be thicker and do not typically have much stretch. For the purposes of this post, we will focus on how to sew leather similar to the kinds that we currently stock. This would be cow, goat, and lambskin with hair off, ranging in thickness from .8mm to 1.2mm, which is what you would most often use for garment-weight leather.

Below is a top list of our recommendations for sewing leather hides:

- Leather needles

- Polyester or nylon thread

- Teflon foot or roller foot

- Stitch Length: longer rather than shorter

- Heavy duty thread (not necessary but looks nicer)

- Tape don’t pin

- Scrap for testing

Let’s dig into the details of what’s in the above recommendation list.

Leather Needles: If you’ve worked with our pleather fabrics you probably used a sharp style need or perhaps a universal, though we don’t recommend a universal as you can get skipped stitches. Regardless, when working with a leather hide, you will have to use a leather needle.

In fact, you’ll probably need a few leather needles, as it’s not uncommon to break a needle or two when sewing through thick areas such as where seams meet. The difference between a leather needle and the other types is that a leather needle has a wedge shape at the tip that pierces the material and allows the thread to pass through it with proper tension.

Sewing Thread: The combination of a leather needle and proper thread will do more for your sewing of leather hides than anything else you do. If you haven’t started with these two items, then stop everything and get these first.

No amount of machine adjustment will make up for improper thread and needle selection. Never use cotton thread when sewing leather as the tannin’s which naturally occur in leather will eventually eat away at the thread.

Bonded nylon thread will give you excellent performance. It is a strong thread and the bonding process gives it extra strength while also reducing friction which lessens the odds of breakage.

Teflon or roller foot: Similar to working with faux leather and stretch vinyl, leather hides can be ‘stickier’ when passing through a sewing machine. This requires that you use either a teflon coated presser foot or roller foot to keep the material moving smoothly through your machine.

Stitch Length: You should err on the side of longer rather than shorter. There are a couple reasons for this. One – you don’t want stitches so close together that the perforations in the leather lead to weakness or ripping. The same goes for sewing clear vinyl or faux leather.

Secondly, if you are using a coarser or more heavy duty thread, it is more visually appealing to have a longer stitch length on leather. We recommend a minimum of 3.5 but usually shorter than what you would use for a basting stitch.

Tape don’t pin: Holes in leather are permanent, so anything that the end user would see you want to avoid. If you pin sections together, the pin holes will be visible later.

You can use double sided tape or leather adhesive to hold two pieces of leather together that you need to sew. This is standard practice in working with leather and if you pull apart commercially sewn leather seams you will often find tape or glue remnants inside the seam.

Scrap for testing: Of all our advice this one is probably the most obvious. Leather is expensive – unlike faux leather which is sold by the linear yard, leather hides are sold by the square foot and can be as much as 5-10 times the cost of imitation leather.

Most retailers of leather hides will have scrap or discount leather available for purchase. While even scrap leather hides may cost more than fake leather fabric, it’s worth the price if it saves you messing up an entire project and having to buy premium leather a second time.

You can use muslin or thick vinyl fabric if you need to test your designs for fit or function. Use the scrap leather hides for confirming your machine setup, thread, and stitch length.

We hope you have enjoyed reading our suggestions and recommendations for working with and sewing leather hides. As always, please send us your questions or comments to mike@MJTrends.com and we’ll happily respond!

Email App

Email App

No Comments